Welcome to the website of Hebi Yuxing Coal Machinery Co., Ltd.!

Hotline:

Product Line

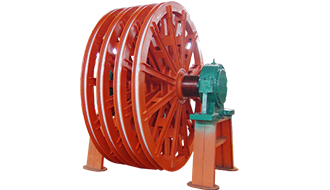

The crown block can be classified into three types: fixed crown blocks installed above the shaft, fixed crown blocks used during shaft sinking and installed below the shaft, and traveling crown blocks. For diameters of 3.5 meters, a press-welded structure is employed; for diameters smaller than 3 meters, a monolithic cast steel structure is used; and for a diameter of 4 meters, a press-riveted structure is adopted.

Learn more

Primarily, it provides lubricating oil to the gear friction pair, forming a film of appropriate thickness between the two meshing tooth surfaces to prevent direct metal-to-metal contact. The circulating oil also helps dissipate heat generated during power transmission and flushes away metallic particles and contaminants produced by normal wear on the gear surfaces, thereby improving transmission efficiency, reducing friction between gears, minimizing wear, lowering power losses, and ultimately extending the equipment's service life.

Learn more

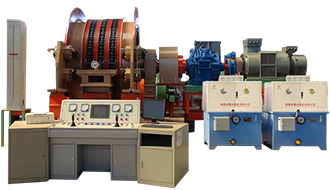

The hydraulic station is the most critical safety and control component of the mine hoist. It works in conjunction with the disc brake system to form a complete braking system, supplying adjustable pressurized oil to the disc brakes, enabling the hoist to generate varying levels of braking torque. In the event of an emergency, the hydraulic station can instantly reduce the oil pressure in the disc brakes down to a pre-set value. After a brief delay, the entire oil pressure in the disc brakes is rapidly released to zero, bringing the entire hoisting system into a fully braked state.

Learn more

Explosion-proof hydraulic station

The explosion-proof hydraulic station is designed for use in mines where the concentrations of methane, coal dust, hydrogen sulfide, carbon dioxide, and other hazardous gases in the surrounding air do not exceed the safety limits specified in the "Coal Mine Safety Regulations."

Learn more

The cylindrical gear reducer is a helical involute cylindrical gear reducer manufactured according to the national professional standard ZBJ19004, designed to transmit power and reduce speed. Thanks to its horizontally split, fully enclosed housing structure, it boasts excellent features such as superior mechanical performance, reliable operation, and convenient maintenance.

Learn more

The parallel-axis gearbox gears are made from high-strength, low-carbon alloy steel through carburizing and quenching, achieving a gear hardness of HR58-62. Additionally, all gears undergo grinding processes, ensuring high precision and excellent contact performance.

Learn more

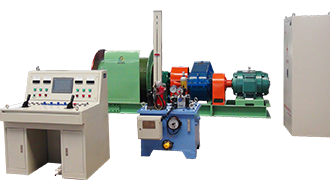

The disc brake is a new type of high-performance braking system and represents the current direction in the development of mechanical brakes. It features a rear-mounted, dual-circuit design powered by hydraulic cylinders, offering advantages such as low inertia, rapid response, excellent adjustability, high reliability, broad versatility, simple installation requirements, and convenient maintenance and adjustment.

Learn more

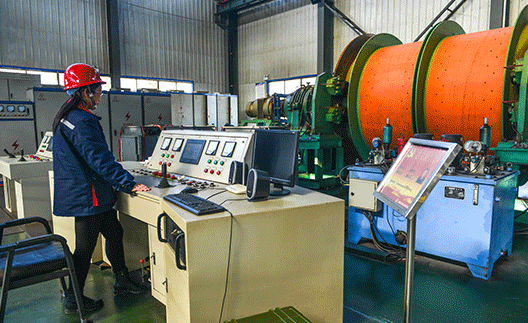

Single-rope winding spindle unit

The spindle assembly consists of components such as the spindle, drum, brake disc, rope-adjusting clutch, hub, bearings, bearing housing, bronze bushings, and plastic liners.

Learn more

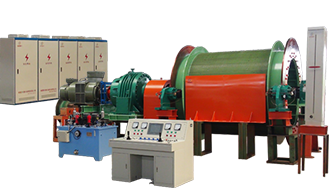

Multi-rope friction spindle unit

The spindle assembly is the working mechanism of the hoist, responsible for transmitting the entire torque required to lift and lower the load, as well as bearing the tensile forces exerted by the steel ropes straddling the friction sheave on both sides. It consists of a spindle, friction sheave, self-aligning roller bearings, bearing housings, bearing covers, bearing beams, friction pads, fixing blocks, and pressure blocks.

Learn more

Follow us

Hebi Yuxing Coal Machinery Co., Ltd.

Hotline:+86-13939219076

Technical Consultation:+86-13503925535

Address: Yuxing Industrial Park, Shancheng, Hebi City, Henan Province

You are a helpful assistant.

Copyright © Hebi Yuxing Coal Machinery Co., Ltd. SEO tags Business license

Copyright © Hebi Yuxing Coal Machinery Co., Ltd.Business license

This website supports IPv6 and SEO tags.