Welcome to the website of Hebi Yuxing Coal Machinery Co., Ltd.!

Hotline:

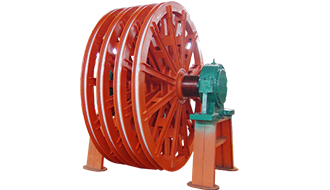

Sky Wheel

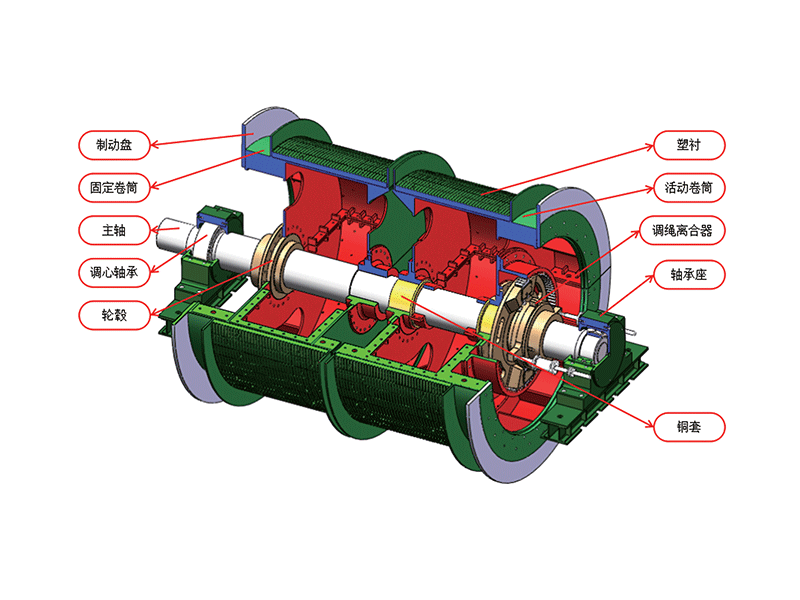

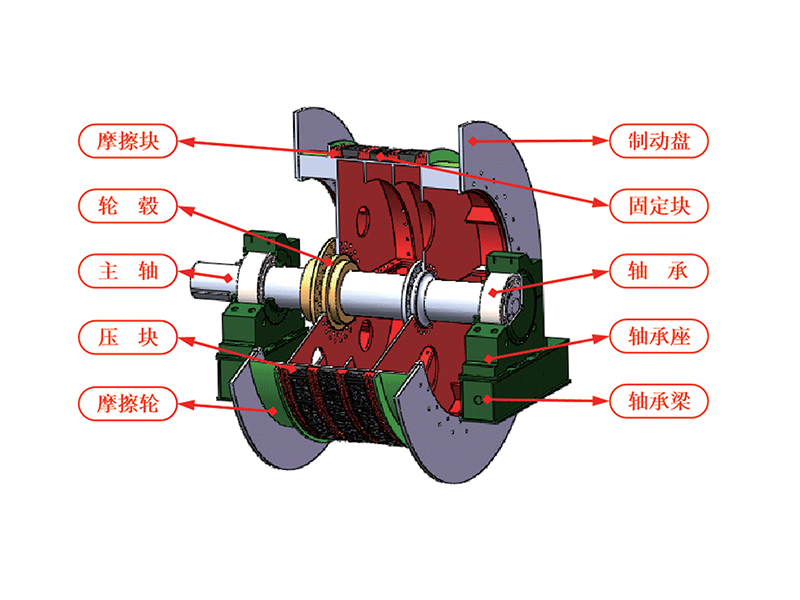

The crown block can be classified into three types: fixed crown blocks installed above the shaft, fixed crown blocks used during shaft sinking and installed below the shaft, and traveling crown blocks. For diameters of 3.5 meters, a press-welded structure is employed; for diameters smaller than 3 meters, a monolithic cast steel structure is used; and for a diameter of 4 meters, a press-riveted structure is adopted.

Category:

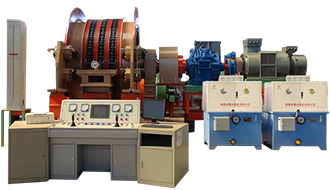

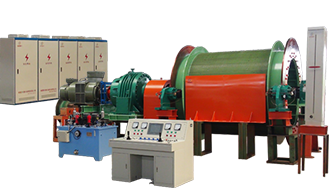

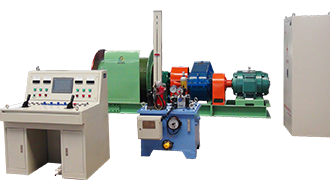

Elevator Accessory Series

Leave a Message Online

Product Description

Product Overview

The crown block can be classified into three types: fixed crown blocks installed above the shaft, fixed crown blocks used during shaft sinking and located below ground, and traveling crown blocks. For diameters of 3.5 meters, a press-welded structure is employed; for diameters smaller than 3 meters, a monolithic cast-steel design is used; and for a diameter of 4 meters, a press-riveted structure is adopted.

At the very top of the mine shaft's headframe, you'll find a fixed pulley that adjusts the direction of the steel wire ropes. This crucial component supports the weight of the cage, skip bucket, or hoisting bucket—and is often regarded as a defining symbol of the mine. (Positioned atop the headframe or in an adit, it serves as the guide wheel that directs the movement of the lifting steel cables.) All according to standards set by the Ministry of Coal Industry.

| Serial Number | Model | Diameter of the rope groove bottom circle D | Rope groove radius R | Maximum swimming distance S | Applicable Steel Wire Rope Diameter | Allowable Total Steel Wire Breaking Strength | Main dimensions | Number of foundation bolts: n | Moment of inertia | Quality | |||||

| L | H | D 1 | A | B | d | ||||||||||

| mm | KN | mm | One | kg·m 2 | kg | ||||||||||

| 1 | TDG 600/9/300 | 600 | 9 | 300 | 14–16 | 160 | 670 | 95 | 690 | 260 | - | 18 | 4 | 4 | 130 |

| 2 | TDG 800/11/700 | 800 | 11 | 700 | >16–20 | 252 | 1100 | 95 | 920 | 260 | - | 18 | 4 | 13 | 220 |

| 3 | TDG 1000/13.5/800 | 1000 | 13.5 | 800 | > 20–24.5 | 382 | 1250 | 130 | 1140 | 350 | - | 26 | 4 | 31 | 425 |

| 4 | TDG 1400/16/740 | 1400 | 16 | 740 | > 24.5–30 | 597 | 1300 | 140 | 1580 | 340 | 60 | 22 | 8 | 105 | 675 |

| 5 | TDG 1400/16/1350 | 1350 | 1900 | 850 | |||||||||||

| Serial Number | Model | Diameter of the rope groove bottom circle D | Rope groove radius R | Applicable Steel Wire Rope Diameter | Allowable Total Steel Wire Breaking Strength | Main dimensions | Moment of inertia A | Quality b | |||||

| L | H | D 1 | A | B | d | ||||||||

| mm | KN | mm | kg·m 2 | kg | |||||||||

| 1 | TLG(H) 1600/10 | 1600 | 10 | > 16–18 | 285 | 600 | 140 | 1750 | 340 | 60 | 22 | 141 | 600 |

| 2 | TLG(H) 1600/11 | 11 | > 18–20 | ||||||||||

| 3 | TLG(H) 2000/12.5 | 2000 | 12.5 | > 20–22 | 413 | 700 | 180 | 2160 | 460 | 80 | 32 | 310 | 845 |

| 4 | TLG (H) 2000/13.5 | 13.5 | > 22–24 | ||||||||||

| 5 | TLG(H) 2500/15 | 2500 | 15 | > 24–26 | 649 | 800 | 200 | 2690 | 485 | 80 | 32 | 860 | 1510 |

| 6 | TLG(H) 2500/16 | 16 | > 26–28 | ||||||||||

| 7 | TLG (H) 2500/17 | 17 | > 28–30 | ||||||||||

| 8 | TLG(H) 3000/18 | 3000 | 18 | >30~32 | 990 | 950 | 240 | 3210 | 600 | 92 | 40 | 1755 | 2490 |

| 9 | TLG (H) 3000/19 | 19 | > 32–34 | ||||||||||

| 10 | TLG(H) 3000/20 | 20 | > 34–36 | ||||||||||

| 11 | TLH 3500/21.5 | 3500 | 21.5 | > 36–39 | 1392 | 1000 | 275 | 3730 | 680 | 108 | 46 | 3410 | 3350 |

| 12 | TLH 3500/23 | 23 | > 39–42 | ||||||||||

| 13 | TLH 4000/24 | 4000 | 24 | > 42–45 | 1720 | 1030 | 300 | 4260 | 740 | 150 | 46 | 5843 | 4850 |

| 14 | TLH 4000/26 | 26 | > 45–48 | ||||||||||

| 15 | TLH 5000/29 | 5000 | 29 | > 48–52 | 2025 | 1030 | 320 | 5280 | 780 | 150 | 54 | 15031 | 6550 |

| 16 | TLH 3500/23.5 | 3500 | 23.5 | > 37–43 | 1392 | 1000 | 275 | 3760 | 680 | 108 | 46 | 3460 | 3730 |

| 17 | TLH 4000/25 | 4000 | 25 | > 43–47.5 | 1476 | 1030 | 280 | 4305 | 680 | 130 | 46 | 8240 | 5320 |

| 18 | TLH 5000/29 | 5000 | 29 | > 47.5–52 | 1780 | 1030 | 300 | 5290 | 740 | 150 | 46 | 17063 | 7280 |

Related Products

Leave a Message Online

Follow us

Hebi Yuxing Coal Machinery Co., Ltd.

Hotline:+86-13939219076

Technical Consultation:+86-13503925535

Address: Yuxing Industrial Park, Shancheng, Hebi City, Henan Province

You are a helpful assistant.

Copyright © Hebi Yuxing Coal Machinery Co., Ltd. SEO tags Business license

Copyright © Hebi Yuxing Coal Machinery Co., Ltd.Business license

This website supports IPv6 and SEO tags.