Welcome to the website of Hebi Yuxing Coal Machinery Co., Ltd.!

Hotline:

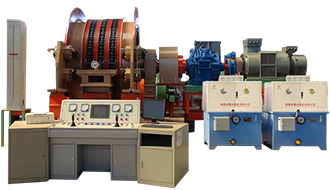

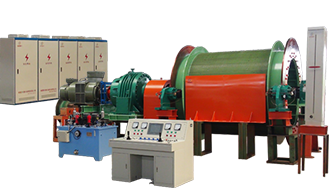

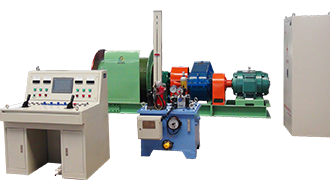

Multi-rope friction spindle unit

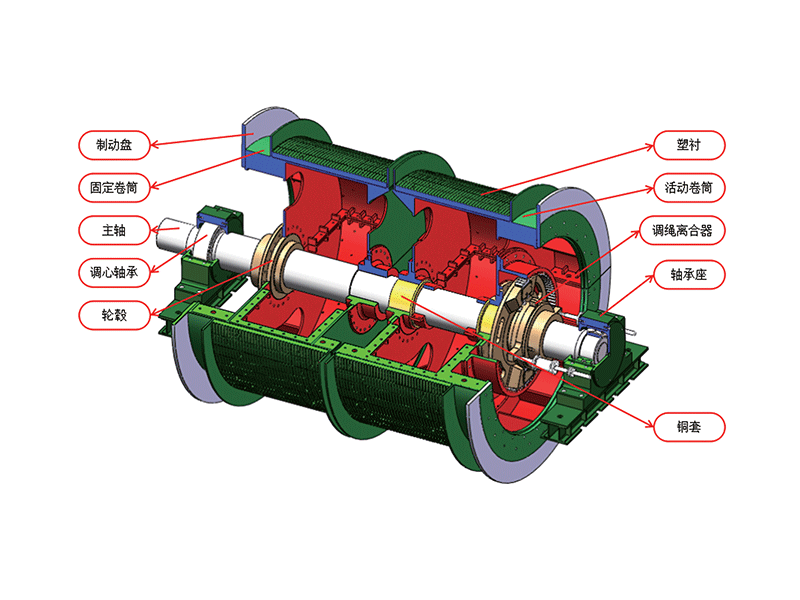

The spindle assembly is the working mechanism of the hoist, responsible for transmitting the entire torque required to lift and lower the load, as well as bearing the tensile forces exerted by the steel ropes straddling the friction sheave on both sides. It consists of a spindle, friction sheave, self-aligning roller bearings, bearing housings, bearing covers, bearing beams, friction pads, fixing blocks, and pressure blocks.

Category:

Elevator Accessory Series

Leave a Message Online

Product Description

Product Overview

The spindle assembly is the working mechanism of the hoist, responsible for transmitting the entire torque required to lift and lower the load, as well as bearing the tensile forces exerted by the steel ropes straddling the friction sheave on both sides. It consists of a spindle, friction sheave, self-aligning roller bearings, bearing housings, bearing covers, bearing beams, friction pads, fixing blocks, and pressure blocks.

The spindle is one of the key components of the spindle assembly—it supports the entire assembly, bears its own weight and external loads, and transmits all torque. It is forged from high-quality low-alloy steel. One or two flanges are directly forged onto the shaft and securely connected to the friction wheel via high-strength, precision-machined bolts.

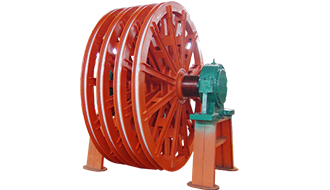

The friction wheel is made of low-alloy steel (Q355), featuring an all-welded structure composed of a cylindrical shell, left and right spoke plates, left and right hubs, support rings, and rope-retaining plates welded together. For large-scale elevators (with diameters of 2.8 meters or greater), support rings are welded inside the cylindrical shell to enhance its overall rigidity.

Depending on customer requirements, either a non-detachable welded brake disc (also known as a fixed brake disc)—where the brake disc is permanently welded to the drum end—or a detachable (split) composite brake disc can be used. In the latter case, the brake disc is divided into two halves and securely mounted onto the friction wheel, which is then connected to the brake disc using high-strength, precision-made bolts.

The main bearing consists of components such as a roller bearing, bearing cap, bearing housing, and bearing end cover. Self-aligning roller bearings offer excellent performance, capable of handling significant radial loads and providing strong resistance to impact—resulting in long service life, high efficiency, and easy maintenance.

The friction pads are critical components, securely fastened to the friction wheel using fixing blocks and pressure blocks attached by bolts. High-friction pads with a coefficient of friction greater than 0.25 are employed to ensure optimal performance parameters, enhanced lifting capacity, and reliable safety. The floor-mounted elevator features two rope grooves, and a rope-switching mechanism allows the steel cables to seamlessly alternate between these grooves. This innovative design effectively doubles the lifespan of the friction pads while also improving the overall efficiency of pad material utilization.

Related Products

Leave a Message Online

Follow us

Hebi Yuxing Coal Machinery Co., Ltd.

Hotline:+86-13939219076

Technical Consultation:+86-13503925535

Address: Yuxing Industrial Park, Shancheng, Hebi City, Henan Province

You are a helpful assistant.

Copyright © Hebi Yuxing Coal Machinery Co., Ltd. SEO tags Business license

Copyright © Hebi Yuxing Coal Machinery Co., Ltd.Business license

This website supports IPv6 and SEO tags.