Welcome to the website of Hebi Yuxing Coal Machinery Co., Ltd.!

Hotline:

Disc brake

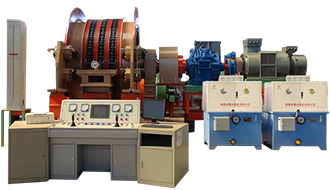

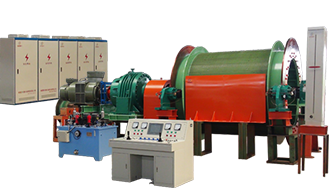

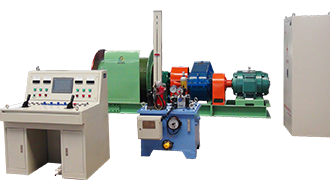

The disc brake is a new type of high-performance braking system and represents the current direction in the development of mechanical brakes. It features a rear-mounted, dual-circuit design powered by hydraulic cylinders, offering advantages such as low inertia, rapid response, excellent adjustability, high reliability, broad versatility, simple installation requirements, and convenient maintenance and adjustment.

Category:

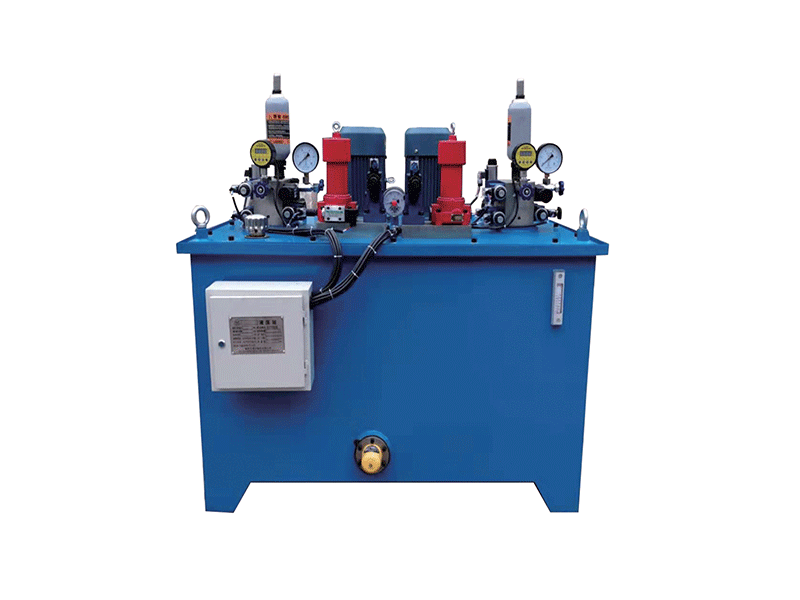

Hydraulic System Series

Leave a Message Online

Product Description

Product Overview

The disc brake is a new type of high-performance braking system and represents the current direction in the development of mechanical brakes. It features a rear-mounted, dual-circuit design powered by hydraulic cylinders, offering advantages such as low inertia, rapid response, excellent adjustability, high reliability, broad versatility, simple installation requirements, and convenient maintenance and adjustment.

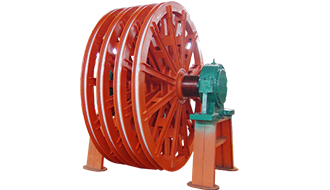

Disc brakes can be used in various types of machinery, including mine hoists, belt conveyors, aerial ropeways, and ship lifts.

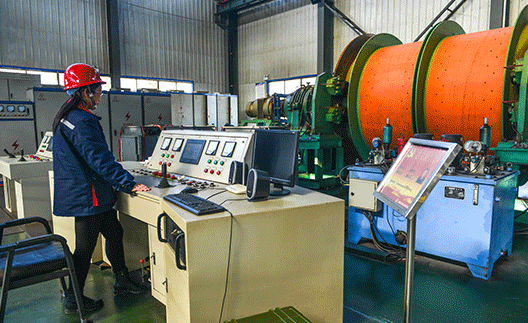

Disc brakes on mine hoists are used for both service and emergency braking, with their actuation and control managed by a separate hydraulic station. The braking torque is generated by brake pads that press axially against the brake disc from both sides. To prevent any additional deformation of the brake disc and ensure the main shaft remains free of extra axial forces, discs are always used in pairs—each pair being referred to as a "disc brake assembly." Depending on the required braking torque, multiple such assemblies can be installed on each hoist unit.

Disc brakes generate braking force through disc springs and are released by hydraulic pressure. In the braking state, the magnitude of the normal force pressing the brake pads against the brake disc depends entirely on the working oil pressure within the cylinder.

The new disc brake system, combined with the hydraulic station, forms the braking system for the mine hoist. The pipelines are connected using push-in fittings, while the cylinders, pistons, and seals have been optimally designed based on advanced foreign products. Notably, the piston incorporates QPQ (Quench-Polish-Quench) technology at low temperatures, significantly enhancing wear resistance and ensuring zero leakage. This innovative design enables the disc brake to deliver both operational and safety braking functions for the hoist. The disc brake is specifically engineered for use as both working and emergency brakes in mine hoisting applications, with its actuation and control managed entirely by a dedicated hydraulic station.

Product Specifications

This product is designed and manufactured in accordance with the JB/T8519-2015 standard, "Disc Brakes for Mine Hoists and Mining Hoist Winches."

Product specifications:

|

Disc Brake Model |

The maximum normal force generated by a brake | Brake shoe design friction coefficient | Maximum allowable temperature for brake shoes | Butterfly Spring Specifications | The brake shoe specific pressure at which maximum positive pressure is generated | Rated Oil Pressure |

| KN | f | °C | Outer diameter × thickness | N/cm2 | MPa | |

|

TP3-40 |

40 | 0.4 | ≤210 | 100 * 6 | 80 | 6.3 |

|

TP3-50 |

50 | 100 × 6.5 | 87 | 6.3 | ||

|

TP3-63 |

63 | 140 × 8 | 84 | 6.3 | ||

|

TP3-80 |

80 | 140 × 9 | 116 | 14 | ||

|

TP3-100 |

100 |

Related Products

Leave a Message Online

Follow us

Hebi Yuxing Coal Machinery Co., Ltd.

Hotline:+86-13939219076

Technical Consultation:+86-13503925535

Address: Yuxing Industrial Park, Shancheng, Hebi City, Henan Province

You are a helpful assistant.

Copyright © Hebi Yuxing Coal Machinery Co., Ltd. SEO tags Business license

Copyright © Hebi Yuxing Coal Machinery Co., Ltd.Business license

This website supports IPv6 and SEO tags.