In the mine's production system, the main inclined shaft hoist stands like a silent giant, entrusted with the critical task of transportation. It serves not only as the vital link between the underground treasures and the surface world but also as the cornerstone ensuring the mine's efficient operation.

I. The Critical Role of the Main Inclined Shaft Hoist

The main inclined shaft serves as the primary transportation artery of the mine, while the main inclined shaft hoist is the core power equipment along this vital route. It plays a critical role in lifting large quantities of materials—such as ore and coal—from underground to the surface, as well as delivering equipment, supplies, and other resources to various working areas below ground. In fact, the stable operation of the main inclined shaft hoist directly impacts the mine's production efficiency and overall economic performance.

For example, in large coal mines, thousands—even tens of thousands—of tons of coal need to be transported daily to the surface using the main inclined shaft hoist. If the hoist breaks down, it can lead to a buildup of coal underground, disrupting production schedules and causing significant financial losses for the company.

II. Operating Principle of the Main Inclined Shaft Hoist

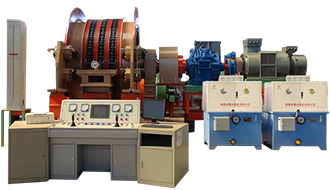

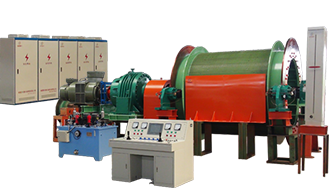

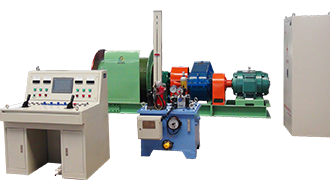

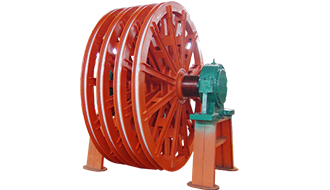

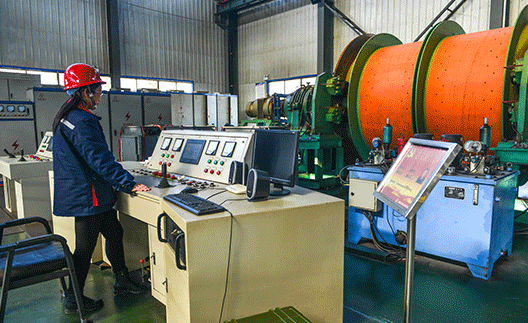

The main inclined shaft hoist typically consists of components such as an electric motor, gearbox, drum, braking system, and control system.

The electric motor delivers powerful torque, which is then converted into a low-speed, high-torque output suitable for the drum via a gearbox. A steel wire rope is wound around the drum, with one end connected to the mine car or skip carrying the material and the other end securely anchored to the drum. As the electric motor rotates the drum, the steel wire rope pulls the mine car or skip up or down along the main inclined shaft track, enabling efficient material transportation.

The braking system is a critical safety safeguard for the main inclined shaft winch—it enables timely braking during operation, preventing the winch from losing control. Meanwhile, the control system monitors and manages the winch’s operational status, ensuring safe and stable performance at all times.

III. Features of the Main Inclined Shaft Hoist

-

Powerful traction

The main inclined shaft hoist typically features high power and strong traction, easily meeting the demands of large-scale material transportation in mines. Whether handling heavy ore or fully loaded mine cars, the main inclined shaft hoist can manage with ease.

-

High reliability

Due to the harsh conditions of the mining environment, the main inclined shaft hoist must exhibit exceptional reliability. It needs to operate reliably over extended periods, even under challenging conditions such as humidity, dust, and vibration, while also featuring robust anti-interference capabilities and advanced self-diagnostic functions for fault detection.

-

Rigorous security performance

The safety performance of the main inclined shaft hoist is critical. It is equipped with multiple safety protection devices, such as overwinding protection, overspeed protection, speed-limit protection, and slack-rope protection, which can promptly shut down the system in case of abnormalities, ensuring the safety of both personnel and equipment.

-

Intelligent Control

With the continuous advancement of technology, the control systems for main inclined shaft winches are becoming increasingly intelligent. Modern main inclined shaft winches typically incorporate advanced PLC control systems, enabling automated operation, remote monitoring, fault diagnosis, and other features—significantly boosting the efficiency of the winch systems.

IV. Maintenance and Servicing of the Main Inclined Shaft Hoist

To ensure the long-term stable operation of the main inclined shaft winch, regular maintenance and upkeep are essential.

-

Daily Inspection

Conduct daily inspections of the winch, checking the operational status of components such as the motor, gearbox, drum, braking system, and wire rope, and promptly identify and address any issues.

-

Regular maintenance

Perform regular maintenance on the winch at prescribed intervals, including replacing lubricants, inspecting the electrical system, and adjusting the braking mechanism. Regular maintenance helps extend the winch's lifespan and enhance its reliability.

-

Professional Repair

When the winch malfunctions, it must be repaired by professional technicians. These technicians should have extensive experience and specialized knowledge, enabling them to quickly and accurately identify the root cause of the problem and implement effective repair measures.

-

Security Training

Conduct regular safety training sessions for winch operators and maintenance personnel to enhance their operational skills. Operators must strictly adhere to operating procedures and are prohibited from leaving their posts without authorization or performing unsafe actions.

V. Development Trends in Main Inclined Shaft Hoists

As the automation and intelligence levels in mining continue to rise, the main inclined shaft hoists are also evolving toward smarter, more intelligent operations.

-

Intelligent Control

The future main inclined shaft hoist will be more intelligent, enabling autonomous operation, smart scheduling, and fault prediction capabilities. By leveraging sensors and advanced data analytics, the hoist can continuously monitor its operational status in real time, anticipate potential failures before they occur, and proactively implement appropriate preventive measures.

-

Effective energy conservation

The main inclined shaft hoist will utilize an electric motor and a transmission system to reduce energy consumption and enhance energy efficiency. Additionally, advanced energy-saving control technologies, such as variable-frequency speed regulation, will be implemented to automatically adjust the hoist’s operating speed based on load conditions, ensuring energy-efficient operation.

-

Smooth and reliable

Smooth operation has always been the primary goal in the development of main inclined shaft winches. Future winches will be equipped with more advanced safety protection systems, such as intelligent braking systems and collision-avoidance technologies, to enhance their operational reliability. At the same time, efforts will be intensified to strengthen winch management, establishing robust safety protocols and comprehensive emergency response plans to ensure seamless and uninterrupted performance.

In short, the main inclined shaft hoist serves as the backbone of mine transportation, playing an indispensable role in mining operations. We should place great emphasis on the operation management and maintenance of the main inclined shaft hoist, continuously improving its level of intelligence to provide strong support for the sustainable development of the mine.