Welcome to the website of Hebi Yuxing Coal Machinery Co., Ltd.!

Hotline:

Multi-rope Friction Hoist Design

2024-11-14

In modern mining, construction, and other heavy-industry sectors, hoists play a critical role. Among them, multi-rope friction hoists stand out as the top choice for many industries, thanks to their unique design and exceptional performance. This article will delve into the design of multi-rope friction hoists, highlighting their remarkable advantages in terms of safety.

I. The Working Principle of Multi-Rope Friction Hoists

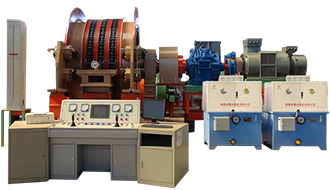

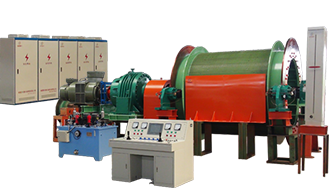

The multi-rope friction hoist primarily consists of a friction sheave, steel ropes, lifting containers, a braking system, and a drive system. Its working principle relies on the frictional force between the friction sheave and the steel ropes to lift or lower heavy loads. As the friction sheave rotates, it transmits motion to the steel ropes via friction, enabling the lifting containers to move vertically up and down within the shaft.

II. Key Elements in the Design of Multi-Rope Friction Hoists

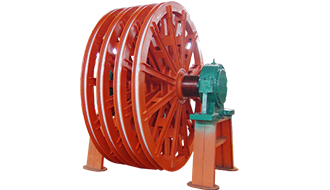

Friction Wheel Design: The friction wheel is one of the core components of a multi-rope friction hoist. Its design must account for several factors, including diameter, width, and material. A larger friction wheel diameter can deliver greater lifting capacity, but it also increases the equipment’s size and weight. The width of the friction wheel should be determined based on the number and diameter of the steel ropes, ensuring sufficient contact area and friction force. Meanwhile, material selection needs to consider wear resistance, strength, and toughness—key factors that guarantee the wheel’s longevity and reliability.

Steel wire rope selection: Steel wire ropes are another critical component of multi-rope friction hoists. The choice of steel wire rope should be determined based on parameters such as the hoist’s lifting height, load capacity, and speed. Generally speaking, the larger the diameter of the wire rope, the greater its load-bearing capacity—but this also increases the equipment’s weight and cost. Additionally, the material, structure, and surface treatment of the wire rope significantly influence its performance and service life. During the design process, it’s essential to select the appropriate wire rope tailored to the specific application, while ensuring proper arrangement and tensioning.

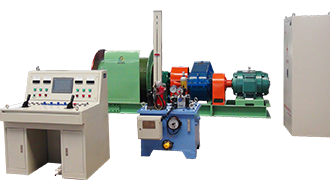

Brake System Design: The brake system is a critical safety feature ensuring the secure operation of multi-rope friction elevators. Its design must meet the following requirements:

- Enable rapid stopping in emergency situations, safeguarding both the elevator and personnel.

- Provide sufficient braking force to handle the elevator's heavy load capacity.

- Ensure smooth braking action, preventing any jarring impacts on equipment or people.

Common brake systems include hydraulic brakes and disc brakes. When designing, it’s essential to select the most appropriate braking method based on specific operational conditions, followed by careful parameter optimization and thorough system debugging.

Transmission System Design: The transmission system serves as the power source for the multi-rope friction hoist. When designing the transmission system, it’s essential to consider key parameters such as the hoist’s lifting speed, load capacity, and required power, ensuring the selection of appropriate components like motors, gearboxes, and couplings. Additionally, the layout and installation of the transmission system must account for factors like space constraints and ease of maintenance. Throughout the design process, meticulous parameter calculations and component selection are necessary to guarantee the system’s reliability.

III. Advantages of Multi-Rope Friction Hoist Design

The multi-rope friction hoist significantly boosts lifting capacity: By utilizing multiple steel cables simultaneously, it outperforms single-rope hoists, enabling much higher lifting capabilities. This makes it ideally suited to meet the demanding high-load requirements of large-scale mining operations and heavy industrial applications.

Smooth Operation: Thanks to multiple steel wire ropes sharing the load evenly, multi-rope friction hoists operate more smoothly, significantly reducing vibration and impact. This not only enhances the equipment's reliability and extends its service life but also ensures greater safety for both personnel and cargo during the lifting process.

High safety performance: Multi-rope friction hoists are typically equipped with comprehensive safety protection systems, including overwinding protection, overspeed protection, and overload protection. These safety features can activate swiftly in emergency situations, ensuring the safe operation of both the hoist and its personnel. Additionally, the braking system of multi-rope friction hoists boasts exceptional reliability and safety, enabling rapid stopping even under critical circumstances.

Easy maintenance: The multi-rope friction hoist features a relatively simple design, making maintenance convenient. Replacing and adjusting the steel cables is also straightforward, helping to reduce equipment maintenance costs and minimize downtime.

IV. Application Cases of Multi-Rope Friction Hoist Design

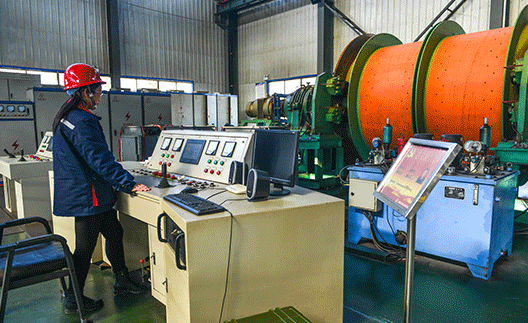

Mining Industry: In the mining sector, multi-rope friction hoists are widely used for mine hoisting. They efficiently and safely lift ores, personnel, and equipment to the surface, significantly enhancing both the productivity and safety of mining operations.

V. Future Development Trends in the Design of Multi-Rope Friction Hoists

Intelligent Design: As technology continues to advance, the design of multi-rope friction elevators will become increasingly intelligent. For instance, by integrating sensor technology and automated control systems, operators can achieve real-time monitoring and control of the elevator’s operational status. Additionally, leveraging artificial intelligence algorithms for fault diagnosis and predictive maintenance will enhance the equipment’s reliability and safety.

Energy-efficient and eco-friendly design: In line with the global trend toward energy conservation and environmental protection, the design of multi-rope friction hoists will increasingly emphasize sustainability. For instance, energy-saving motors and advanced transmission systems will be incorporated to reduce equipment energy consumption. Additionally, optimizing the arrangement and tensioning methods of steel ropes will minimize friction and wear, thereby extending the lifespan of the ropes.

Large-scale and high-speed design: As industrial production continues to advance, the demands for hoisting capacity and speed in elevators are steadily increasing. Looking ahead, multi-rope friction hoists will evolve toward larger sizes and higher speeds. For instance, designs will feature friction wheels with greater diameters and thicker steel cables to enhance lifting power, while integrating high-speed motors and cutting-edge transmission technologies to boost operational speed.

In summary, the design of multi-rope friction hoists is a complex yet critical engineering task. Through thoughtful design and optimization, the inherent advantages of multi-rope friction hoists can be fully realized, enhancing both the performance and reliability of the equipment—and providing robust support for advancements across various industries. Looking ahead, as technology continues to evolve and application demands grow ever higher, the design of multi-rope friction hoists will also undergo ongoing innovation and refinement.

Follow us

Hebi Yuxing Coal Machinery Co., Ltd.

Hotline:+86-13939219076

Technical Consultation:+86-13503925535

Address: Yuxing Industrial Park, Shancheng, Hebi City, Henan Province

You are a helpful assistant.

Copyright © Hebi Yuxing Coal Machinery Co., Ltd. SEO tags Business license

Copyright © Hebi Yuxing Coal Machinery Co., Ltd.Business license

This website supports IPv6 and SEO tags.