Welcome to the website of Hebi Yuxing Coal Machinery Co., Ltd.!

Hotline:

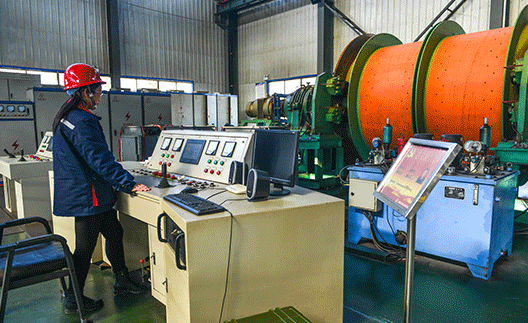

Take you on a journey to uncover the secrets of winch operation.

2024-07-29

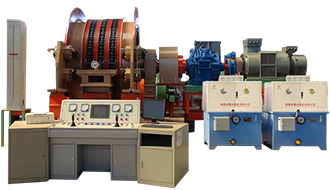

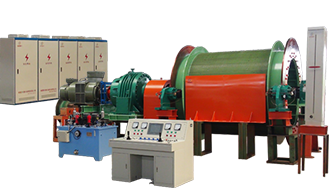

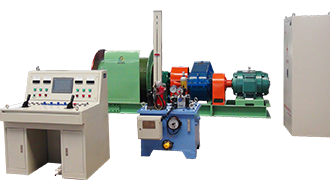

I. Basic Components of a Winch

Electric motor

The motor is the power source that drives the winch. It provides the necessary torque and rotational speed, determining the winch's operational efficiency and load-carrying capacity. For instance, in some large-scale winches, high-power motors are often used to meet the demands of heavy-load lifting or towing applications.

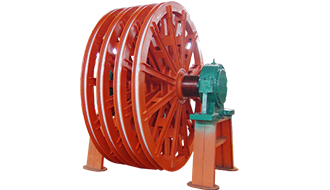

Roller

The drum is one of the key components of a winch. Its primary function is to wind and unwind the steel cable, enabling the cable to be reeled in or out via rotation, thereby facilitating the lifting or pulling of materials. Typically, braking mechanisms are incorporated into the drum design, allowing it to stop rotating promptly when necessary, ensuring operational safety.

Brake

The brake plays a critical role in ensuring safety during winch operation. It can quickly engage the drum when the winch stops, in case of sudden emergencies, or whenever stable positioning of the winch is required—preventing the drum from continuing to rotate and thereby avoiding potential accidents. Depending on the specific working conditions and requirements, brakes come in various types, such as disc brakes and band brakes.

Clutch

The clutch allows control over the operation and stopping of the winch. During winch operation, engaging and disengaging the clutch enables the transmission or interruption of power to the winch, making it easier to perform precise maneuvers and maintain full operational control.

Transmission system

The transmission system is responsible for transferring the power generated by the motor to the drum and other components. Common types of transmissions include gear drives, belt drives, and more, all of which can efficiently adjust torque and rotational speed to meet various operating conditions and requirements.

These key components work together seamlessly to ensure the smooth operation of the winch, with each part playing an indispensable role that enables the winch to safely and efficiently perform its tasks under a wide range of operating conditions.

2. Power Source for the Winch

Electric

Electric power is one of the common methods used to drive winches. Electric winches are easy to use—no specialized technical training is required to get started. They also have relatively low maintenance costs, as they only need occasional inspections and routine upkeep. Installation is straightforward too, requiring just the connection of a power source and a control system. In general, electric winches offer relatively modest lifting capacities, making them ideal for handling and transporting smaller items—such as in light industrial production or small-scale construction projects. However, electric winches are heavily dependent on a stable power supply; any fluctuations in electricity can disrupt their performance. Additionally, their control precision tends to be lower, limiting their ability to execute complex motion tasks.

Manual

A manual winch lifts heavy objects by manually operating a crank or handle. It’s ideal for hoisting lighter items such as tools, accessories, and construction materials. The key advantages of a manual winch include its simple design, low cost, and independence from external power sources or conditions. In situations where electricity is scarce or where frequent mobility is required, the manual winch offers distinct benefits. However, it suffers from lower efficiency, demanding significant manpower and time to complete lifting tasks. Additionally, its load capacity is relatively limited, typically ranging from 0.25 to 5 tons.

Hydraulic

Hydraulic winches are powered by hydraulic fluid, offering a reliable power source that remains unaffected by unstable electricity supply or aging wiring. They deliver substantial lifting capacity—typically ranging from several tons to tens of tons—making them ideal for hoisting and transporting large-scale machinery. Moreover, these winches boast high control precision, enabling intricate motion adjustments via their advanced hydraulic systems. This versatility makes them suitable for a wide range of applications, especially in harsh environments such as extreme temperatures, high humidity, or corrosive conditions—where they can still operate reliably. However, hydraulic winches come with higher maintenance costs, as components like hydraulic fluid and filters require regular replacement. Additionally, installation can be challenging, often necessitating the expertise of professional technicians for proper setup and calibration. As a result, the overall cost of acquiring and maintaining these systems tends to be relatively high.

In summary, different power systems each have their own unique features and suitable applications; therefore, when making a selection, it’s important to carefully consider both your specific needs and the working environment.

3. The Operating Principle of the Winch

Winding and Unwinding Principles

A winch lifts or lowers heavy objects, or moves them horizontally, by winding and unwinding ropes, chains, or steel cables. When a motor or other power source provides the energy, it drives the drum to rotate. As the drum turns, the rope, chain, or cable—fixed securely to the drum—gets either wound around or released from the drum, enabling the controlled movement of the load.

For example, when lifting a heavy object, the power source rotates the winch clockwise, causing the rope to wind steadily around the drum and gradually hoist the weight upward. Conversely, when lowering the object, the winch turns counterclockwise, releasing the rope and allowing the weight to descend smoothly.

In scenarios involving horizontal movement, the principle is similar—only the direction of the rope's pull changes.

The mechanical principles involved

During the operation of the winch, several mechanical principles are at play. First is force transmission: the torque generated by the power source is efficiently transferred to the drum via a transmission system, causing the drum to rotate.

Next is the role of friction: friction exists between the rope and the winch, ensuring that the rope doesn’t slip during winding or unwinding, thus enabling the stable lifting, lowering, or moving of heavy objects.

Moreover, the weight of the object is also a critical factor. When lifting a heavy load, the power source must generate enough force to counteract the object's gravitational pull. Conversely, when lowering the load, it’s essential to carefully regulate the winch’s rotation speed to prevent the object from accelerating rapidly downward due to gravity.

Mechanical principles involved

The mechanical design of the winch is also critical to its proper operation. For instance, gear or belt drives in the transmission system allow for the adjustment of rotational speed and torque—achieved through a rational ratio of gear teeth or pulley diameters—to meet various operational requirements.

The structural design of the reel must consider its load-bearing capacity and the method of rope winding, ensuring that the rope winds and unwinds smoothly and in an orderly manner, preventing tangling and jamming.

Additionally, the mechanical design of the braking system must enable quick and reliable braking of the winch whenever needed, ensuring operational safety.

4. Operating Procedures for the Winch

(1) Preparations Before Driving

- Inspect the integrity of all winch components, including connectors, locking devices, bolts, pins, and more, for any signs of looseness or detachment. Pay particular attention to ensuring that the foundation bolts and bearing housing mounting bolts are securely tightened.

- Ensure that the operating mechanism and transmission linkages of the braking system move smoothly and reliably, that the clearance between the brake wheel and brake shoes meets the specified requirements, and that the travel of the operating handle during braking does not exceed 3/4 of its full stroke.

- Check the accuracy of the depth indicator, and verify that protective devices such as overwinding, overspeed, overcurrent, undervoltage, deceleration alarms, and foot switches operate sensitively and reliably.

- Check the sensitivity of the appliance operation buttons and ensure that signals, switches, control devices, motors, and other components are intact and undamaged.

- Check the tightness of tie rods, compression rods, and bases for any signs of looseness or rust.

- Check the drum wire rope for rope biting, strand breaks, and wire breaks, ensuring the wire rope is neatly and normally wound/unwound while maintaining proper lubrication.

- For the hydraulic winch, check the oil tank level, oil temperature, and ensure that the cooling water flows freely. Verify that all oil pressure gauges indicate normal readings, the electro-hydraulic valve is fully open with proper stroke, the control lever is in the neutral position, the ball valve is in the open position, and there are no oil leaks in the hydraulic lines.

- Check that the signaling system is clear, unobstructed, and accurate, and confirm receipt of a clear and precise departure signal.

(II) Key Operational Points During Operation

- Drive strictly according to the signals; never start moving if the signal is unclear or not clearly heard.

- When starting up, operate smoothly, ensuring that the controller handle and working brake movements are well-coordinated. Absolutely avoid abruptly jerking the handle.

- During operation, stay fully focused and closely monitor all instruments, indicator lights, depth indicators, as well as the alignment and tension of the wire rope. Pay attention to any unusual sounds, odors, or signs of malfunction in various parts of the winch.

- It is strictly prohibited to release heavy objects by loosening the brake when the motor is not energized.

- Pay attention to the winch's load conditions and stop immediately if you notice a sudden increase in load for troubleshooting.

- Monitor the condition of the wire rope at all times; if you notice severe rope biting, rope climbing, broken wires, or any other abnormal signs, stop the equipment immediately for inspection and repair.

- Absolutely no driving while standing on the traction side, and absolutely no simultaneous braking using both brake levers.

- When the winch drum is frequently subjected to counter-torque, ensure that both brakes are in proper contact for safe and reliable operation.

(III) Precautions When Parking

- When approaching the parking position, first gently tighten the brake while slowly releasing the working brake to gradually slow down the winch. Once you hear the stop signal, firmly engage the brake, release the working brake, stop the winch, and then cut off the power supply.

- When lifting the mine car, after it passes the upper-grade transition point, the operator must stop precisely—parking too short or overwinding is strictly prohibited.

- After parking normally, you should activate the warning red lights. If leaving for an extended period, be sure to disconnect the power and lock the vehicle.

- After parking, all levers should be placed in the correct position. If the vehicle will remain parked for an extended period, be sure to engage the brake lever firmly.

- Regularly inspect all parts of the winch, address any issues promptly, and immediately report anything beyond your ability to resolve.

- Carefully complete the winch operation log.

V. Key Factors for Winch Operation

Motor stability

The stability of the motor directly affects the operational efficiency and safety of the winch. A stable motor ensures consistent torque and rotational speed, preventing any erratic fluctuations or interruptions during the winch's operation. For instance, if the motor experiences unstable speed during runtime, it could lead to uneven lifting or pulling speeds, disrupting workflow progress—and potentially even causing safety hazards. Moreover, motor stability helps minimize stress on the transmission system and other components, ultimately extending the overall lifespan of the winch system.

Precision of the transmission system

The precision of the transmission system determines the accuracy and efficiency of power delivery. A high-precision transmission ensures that the motor’s power is accurately and reliably transferred to components like the drum, minimizing energy loss and mechanical wear. Conversely, insufficient transmission precision can lead to uneven torque transfer, causing vibrations and increased noise during winch operation—and may even result in premature failure of critical components.

Reliability of the braking system

The reliability of the braking system is critical to ensuring the safe operation of the winch. A dependable braking system can quickly and accurately stop the winch whenever necessary, preventing accidents from occurring. For instance, in sudden emergencies or when it’s required to halt the winch immediately, a braking system that fails to respond promptly could lead to severe consequences, such as heavy objects falling or equipment being damaged. Moreover, a well-designed braking system also guarantees the winch remains stable even when stationary.

Operators' skills

The skill level of operators is critical to the smooth operation of winches. Skilled and highly proficient operators can accurately assess the winch’s operational status, promptly identify potential issues, and take appropriate corrective actions. They are capable of precisely controlling the winch’s start-up, stoppage, speed, and direction according to job requirements, thereby preventing equipment failures and safety incidents caused by improper handling. Additionally, experienced operators can flexibly adapt their techniques based on varying work scenarios and load conditions, ensuring the winch operates efficiently and effectively in every situation.

6. Safety Measures for Winch Operation

(1) Installation of Safety Circuits

Safety circuits play a critical role in hoist operation. Typically, these circuits encompass multiple protective measures, including overwinding protection, overspeed protection, and overload protection. For instance, the overwinding protection device immediately activates when the hoist drum exceeds its predefined upper or lower limit, causing the hoist to stop and preventing potential collision accidents. Similarly, the overspeed protection system responds swiftly if the hoist’s operating speed surpasses the set threshold, initiating timely braking. The reliable implementation of these safety features depends on precise sensors and robust control logic, ensuring that power is instantly cut off under any abnormal conditions—thus safeguarding both the hoist and the operators.

(II) Self-Diagnosis Function for Faults

The winch's self-diagnosis function enables real-time monitoring of the winch's operational status. It can automatically detect issues such as motor overheating, electrical system faults, and abnormalities in the transmission mechanism. When a potential fault is identified, the system triggers an alarm and displays a fault code, allowing maintenance personnel to quickly pinpoint and resolve the problem. For instance, if the motor temperature exceeds the preset threshold, the self-diagnosis system immediately activates an alert, prompting operators to stop the machine for inspection and preventing motor damage. Additionally, the self-diagnosis feature logs the exact time of the failure along with relevant parameters, providing valuable data for future fault analysis and preventive maintenance efforts.

(III) How the Safety Braking System Works

The safety braking system primarily operates based on the principle of friction. When braking is required, the braking mechanism applies pressure, bringing the brake pads into tight contact with either the brake disc or brake drum, generating powerful friction that rapidly reduces the winch’s rotational speed—eventually bringing it to a complete stop. For instance, in the event of a sudden emergency, the safety braking system responds instantly, applying immense braking force to quickly halt the drum’s rotation and prevent the situation from escalating into a more serious accident. Additionally, to ensure reliable braking performance, the system typically incorporates a redundant design—featuring multiple braking components or backup braking methods—to handle extreme scenarios where the primary braking system might fail.

Follow us

Hebi Yuxing Coal Machinery Co., Ltd.

Hotline:+86-13939219076

Technical Consultation:+86-13503925535

Address: Yuxing Industrial Park, Shancheng, Hebi City, Henan Province

You are a helpful assistant.

Copyright © Hebi Yuxing Coal Machinery Co., Ltd. SEO tags Business license

Copyright © Hebi Yuxing Coal Machinery Co., Ltd.Business license

This website supports IPv6 and SEO tags.