Welcome to the website of Hebi Yuxing Coal Machinery Co., Ltd.!

Hotline:

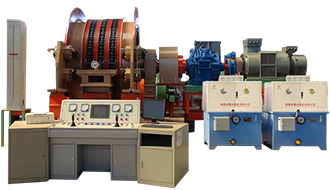

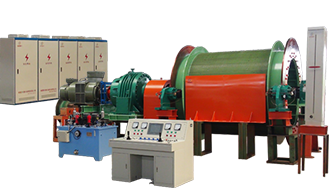

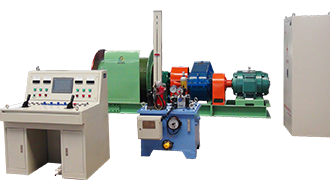

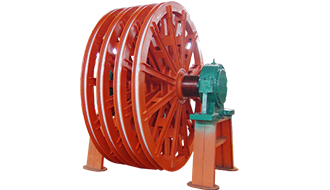

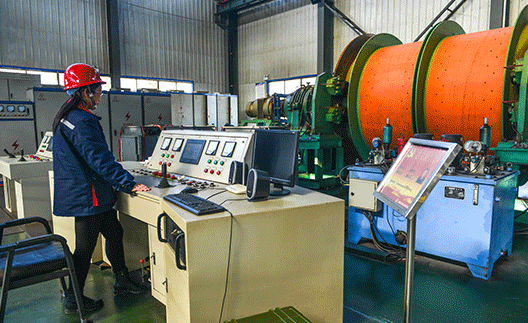

Multi-rope Friction Hoisting Carriage Device

2022-07-07

Multi-rope friction hoisting machine car trough device:

(1) Purpose of the Grooving Device

The newly installed multi-rope hoist requires grooving on the friction pads before operation to ensure uniform diameter across all rope grooves, thereby maximizing the contact area between the wire ropes and the friction pads. Additionally, during operation, uneven wear in the grooves—caused by various factors—can lead to differences in groove diameters, resulting in inconsistent tension among the individual wire ropes. To maintain a more balanced load distribution across all ropes, regular adjustment and resurfacing of the grooves are essential. This is why a dedicated grooving device is necessary.

(2) Structure of the Well Tower-Type Car Slotting Device

Each friction pad on the friction wheel has a corresponding, independent lathe tool assembly, allowing for individual turning operations. When machining rope grooves, first align each tool precisely with the calibration ruler (or straightedge), then adjust the scale dials on all tool assemblies to zero (or to the same numerical value). Afterward, rotating the handwheel will move the tool holder within the tool sleeve, enabling either feed or retract movements. The handwheel is fitted with a graduated ring, making it easy to read the exact feed or retract distance directly from the scale. Specifically, each click of the handwheel advances or retracts the tool by 0.1 mm, while one full rotation moves the tool forward or backward by 2 mm. This process continues until the rope groove is fully turned and all tools have been fed to the same depth setting—ensuring uniform cutting across the entire groove. Importantly, the maximum cutting depth for machining the rope groove is determined based on the smaller groove diameter. This approach minimizes the cutting load, thereby extending the service life of the friction pads.

Follow us

Hebi Yuxing Coal Machinery Co., Ltd.

Hotline:+86-13939219076

Technical Consultation:+86-13503925535

Address: Yuxing Industrial Park, Shancheng, Hebi City, Henan Province

You are a helpful assistant.

Copyright © Hebi Yuxing Coal Machinery Co., Ltd. SEO tags Business license

Copyright © Hebi Yuxing Coal Machinery Co., Ltd.Business license

This website supports IPv6 and SEO tags.