Welcome to the website of Hebi Yuxing Coal Machinery Co., Ltd.!

Hotline:

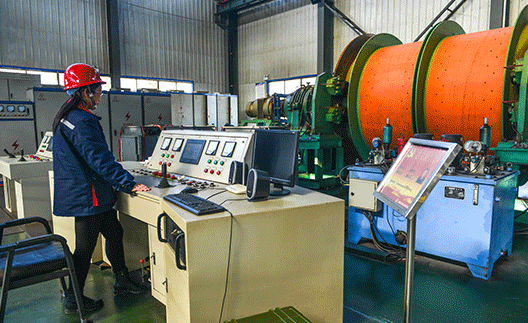

From the perspective of a mining equipment manufacturer, let's discuss the causes of abnormal sounds in mine hoist motors, as well as reasons for reduced motor speed or complete motor failure.

2022-07-29

If your mine hoist experiences abnormal motor noises, reduced motor speed, or even complete shutdown during operation, you might feel unsure about how to proceed—perhaps even overwhelmed. Your first instinct may be to call the hoist manufacturer for advice. However, experienced electricians already know exactly how to address these issues. So, let me walk you through some practical solutions for dealing with abnormal motor sounds, low motor speeds, or motor failures.

The abnormal sound of the mine hoist motor, along with reduced motor speed or complete motor failure, is primarily caused by the following factors:

1. Motor Overload

Here, motor overload is mentioned. Let’s now take a brief look at the underlying causes of motor overloads—many people only know one side of the story while missing the other. Also, a friendly reminder: please ensure proper protection against motor overloads, as burning out the motor windings could lead to costly repairs down the line.

1. Overloading equipment like motors can easily lead to motor failure. For instance, a mine hoist rated for a maximum static tension of 140 kN, if tasked with lifting a load of 150 kN, will likely experience reduced speed—and in cases of severe overloading, the motor could even stop completely. Moreover, operating a mine hoist beyond its capacity jeopardizes safe coal mining operations, potentially leading to accidents that could have been prevented altogether. Remember: No machinery, including mine hoists, should ever be operated beyond its designed limits!

Solution: Operate according to the rated load specified in the mine hoist’s instruction manual.

2. The mine hoist has not been lubricated internally for an extended period. Even though we’re operating it at the rated load specified in the manual, the motor is still experiencing overload. In this case, we need to check whether lubrication is required inside the hoist—specifically, verify if the gear oil in the gearbox and the grease in the drum need replenishing. Failure to lubricate the mine hoist increases friction between the gears, which can ultimately lead to motor overload when the hoist starts spinning on its own.

Solution: The mine hoist should be regularly lubricated with oil and grease as per regulations—typically based on the operating hours of the hoist.

2. Undervoltage

Let’s break this down into simpler, more conversational English while keeping the tone informative and engaging: "Here’s a quick science lesson on electricity: When voltage drops too low, it can cause excessive current flow—leading to serious overheating in motors! To prevent this, we recommend using an appliance protector. It’s your safety net for smart, efficient, and reliable energy use. By safeguarding your devices from abnormal grid voltages or power supply issues, it helps avoid damage like burning out, getting destroyed, or even causing fires—keeping both your life and property safe and sound. And at the end of this article, I’ll walk you through exactly how these protectors work!"

1. The mine hoist is located too far from the power supply transformer.

Solution: Move the power supply transformer closer to the mine hoist.

2. If the voltage at the wellhead is normal, but the voltage inside your well is too low, it indicates that the electricity supplied by the power company is generally stable—however, the internal wiring in your well simply lacks sufficient capacity, causing a significant drop in voltage. This issue likely stems from aging wires or insufficient upgrades to handle the current load.

Solution: Increase the cable diameter

3. Does the motor fan cover of the mine hoist come into contact with and rub against the fan blades?

1. The iron-sheet protective cover used for the mine hoist motor fan tends to deform or dent under external force, causing the fan blades to come into contact with the cover. This can also result in unusual noises when the motor is started.

Solution: Remove and trim the motor fan cover; if the cover is severely damaged, it must be replaced with a new one.

2. Foreign objects have entered the motor fan housing of the mine hoist, or a fan blade has broken off inside the housing—both scenarios can cause unusual noises when the motor is running.

Solution: Clear any foreign objects from inside the motor fan cover. If the fan blades are broken, replace them promptly to ensure proper motor cooling!

Follow us

Hebi Yuxing Coal Machinery Co., Ltd.

Hotline:+86-13939219076

Technical Consultation:+86-13503925535

Address: Yuxing Industrial Park, Shancheng, Hebi City, Henan Province

You are a helpful assistant.

Copyright © Hebi Yuxing Coal Machinery Co., Ltd. SEO tags Business license

Copyright © Hebi Yuxing Coal Machinery Co., Ltd.Business license

This website supports IPv6 and SEO tags.