Welcome to the website of Hebi Yuxing Coal Machinery Co., Ltd.!

Hotline:

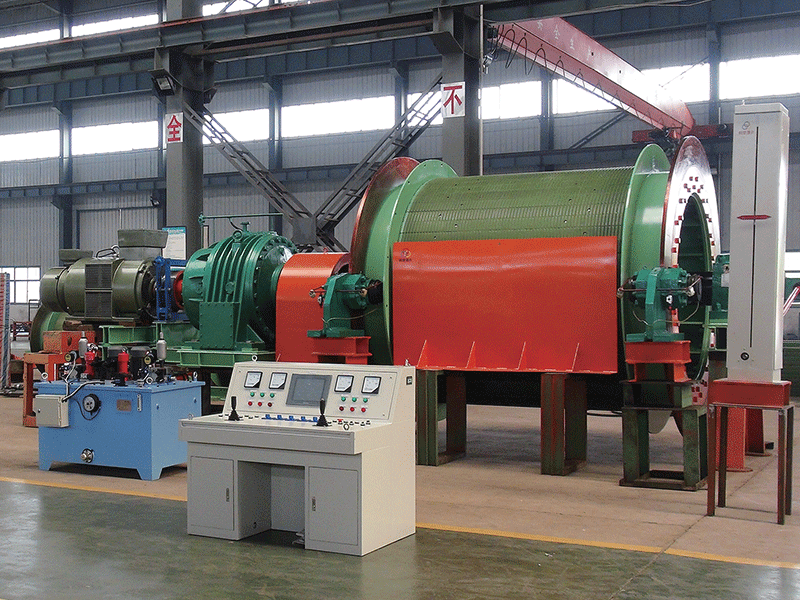

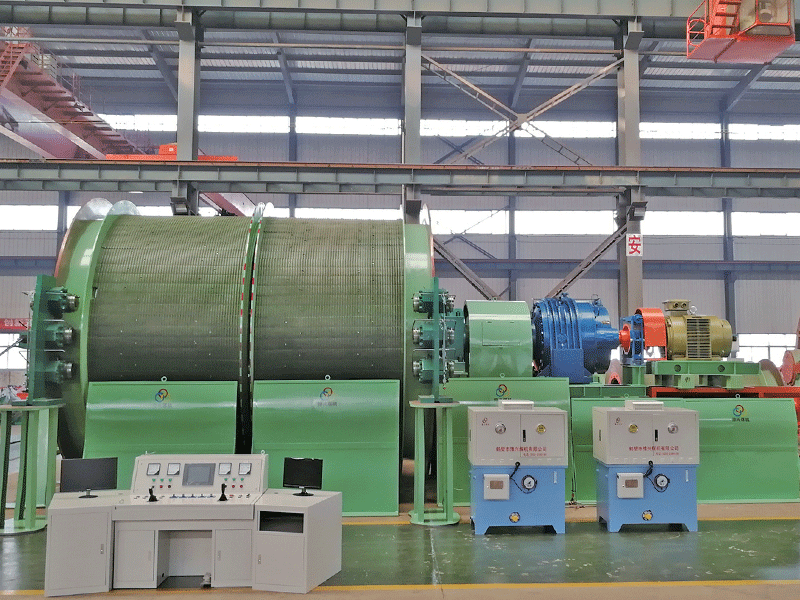

Mining hoisting winch

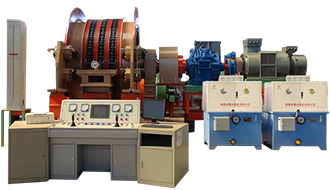

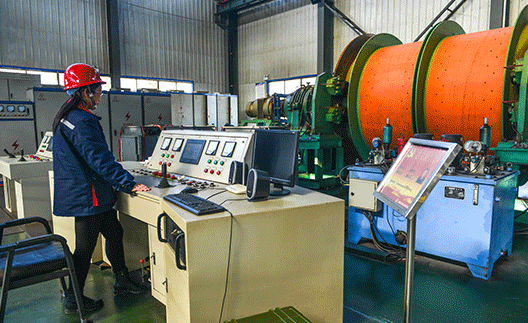

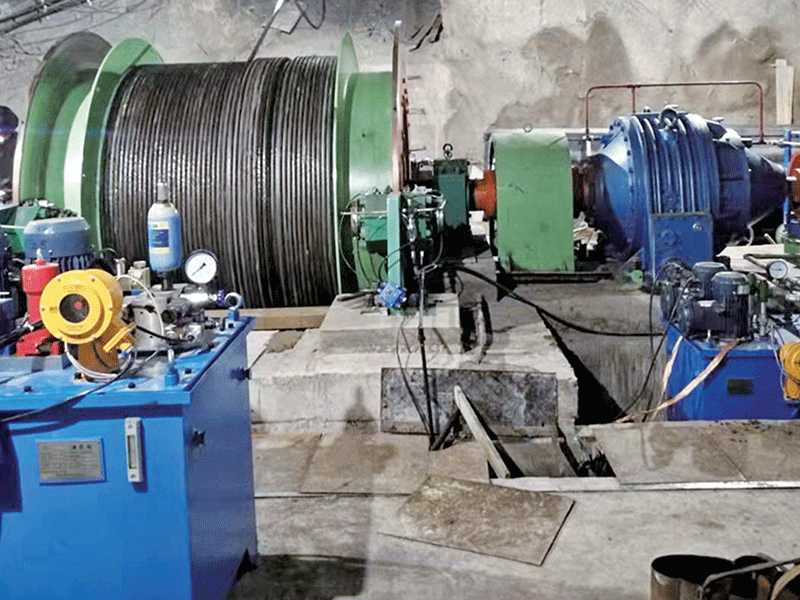

The explosion-proof hoisting winch, specifically designed for coal mines, is used to lift or transport personnel and materials underground. Its配套 explosion-proof electrical control system ensures enhanced safety. This lightweight and compact lifting device employs a drum to wind steel cables or chains, enabling the lifting or pulling of heavy loads. It features one or more horizontally mounted drums—or cable drums—capable of winding ropes, and is primarily utilized in mining operations for hoisting materials or towing them horizontally.

Category:

JTP-Type Mine Hoisting Winch

Leave a Message Online

Product Description

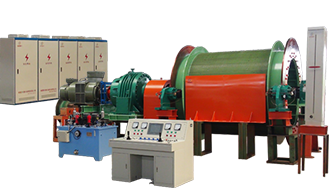

Metal and Non-metal Mine hoisting winch (Applicable to both aboveground and underground areas of the mine), Underground Explosion-Proof Winch for Coal Mines (Click to learn more about the parameters) — The winch drum can be easily lowered into the well either in two or four separate sections. Suitable for hoisting and transportation in main shafts, auxiliary shafts, inclined shafts, and vertical shafts. 。 Used for 20-meter to 2,300-meter mine shafts. Single-trip hoisting capacity ranges from 2 tons to 23 tons. The lifting methods differ between inclined shafts and vertical shafts; even with the same model of hoisting equipment, the maximum weight that can be lifted varies depending on the type of shaft. For inquiries, please call the number listed on the page.

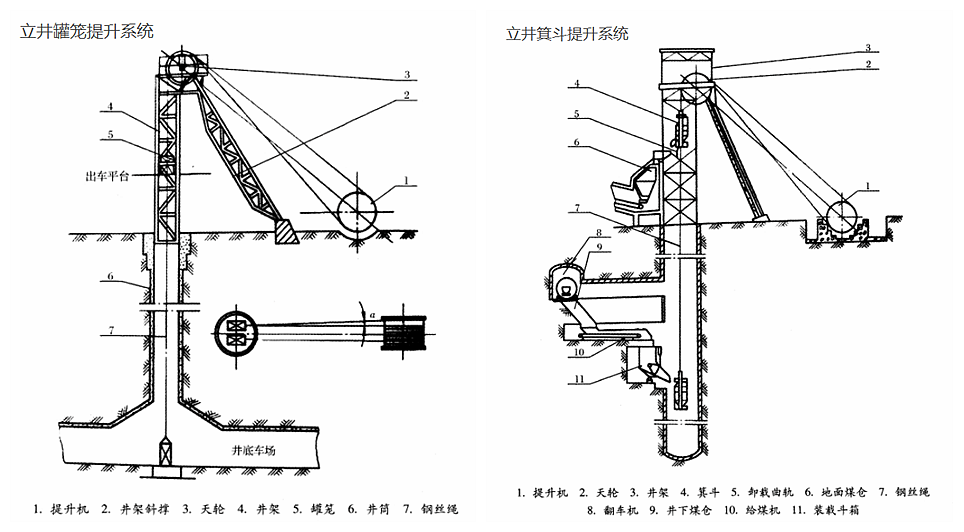

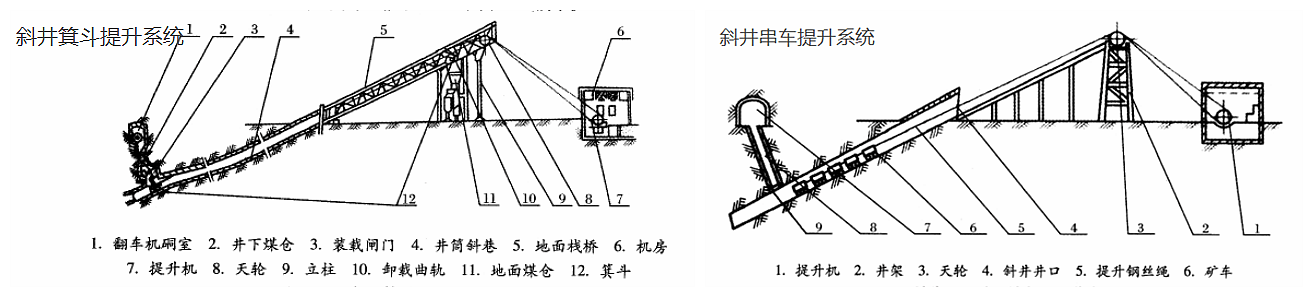

The mine hoisting system is divided into: Shaft hoisting or inclined shaft hoisting:

① The shaft hoisting system is further divided into the cage hoisting system and the skip hoisting system. The shaft cage hoisting system is typically used as a secondary shaft system (and can also serve as a hybrid shaft system; in smaller mines, it sometimes even doubles as the main shaft hoisting system). In contrast, the shaft skip hoisting system exclusively functions as the main shaft system. Compared to the secondary shaft system, aside from the difference in containers, this system employs both mechanical and automated methods for loading and unloading, making it easier to implement fully automated operations.

② Inclined shaft skip and cage hoisting system. The inclined shaft skip hoisting system is part of the main shaft hoisting system, while the cage-and-ropeway hoisting system typically serves as the auxiliary shaft hoisting system. In mines with lower production volumes, this system may even double as the primary hoisting system for coal or other materials. Meanwhile, the inclined shaft cage-and-ropeway system can function either as a main shaft hoisting system or as a supplementary lifting system. When transporting materials up and down, mine cars and material carts are commonly used. However, when it’s time to transport personnel, the cages can be detached and replaced with passenger cars to safely carry workers.

Mine hoists, also known as winch elevators, are compact and lightweight lifting devices that use a drum to wind steel cables for raising or pulling heavy loads. These machines feature one or more horizontally mounted drums—or cable drums—designed to neatly coil ropes, and they are primarily used in mining operations for lifting materials vertically or dragging them horizontally.

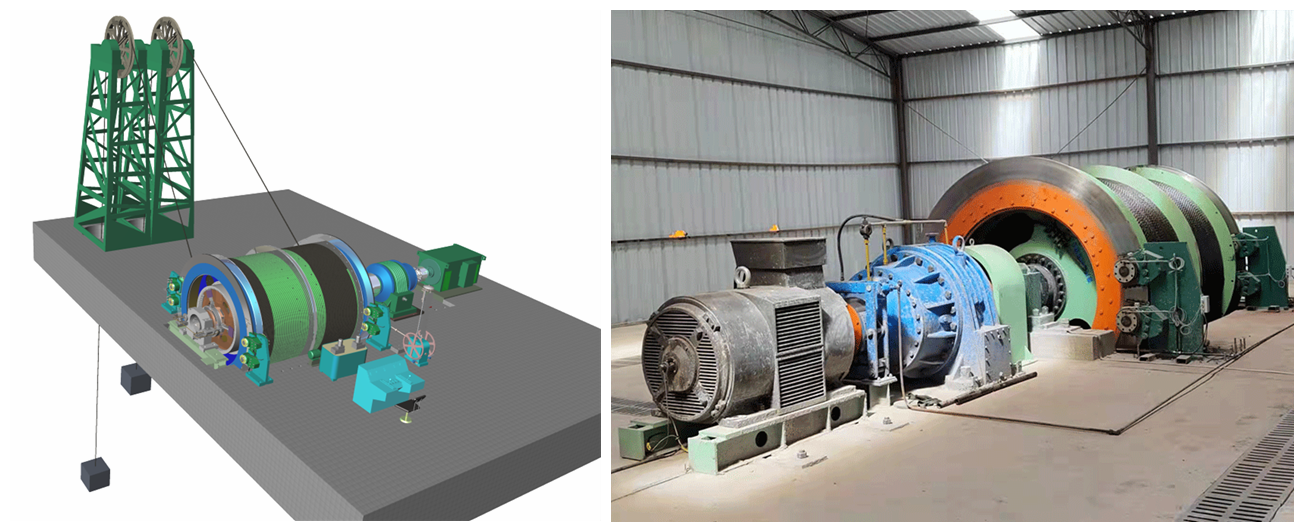

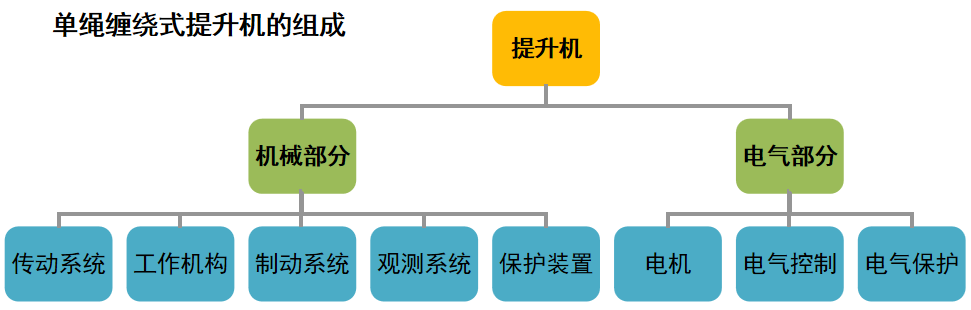

Working Principle of Single-Rope Winding Mine Hoists :

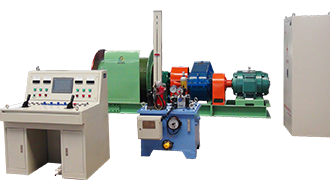

Powered by an electric motor, the system utilizes a coupling, gearbox, spindle assembly, and sheave assembly as its transmission and operational components, employing steel cables to lift and lower containers within the shaft. A series of control systems, including brakes and depth indicators, ensures the equipment operates smoothly and reliably.

The motor speed is adjusted via the gearbox to achieve a specific rotational speed for the drum, which in turn ensures that the steel cable wound around the drum moves the container at the desired linear velocity.

The floating drum of the double-drum hoist can rotate relative to the fixed drum, enabling rope adjustment.

|

|

|

|

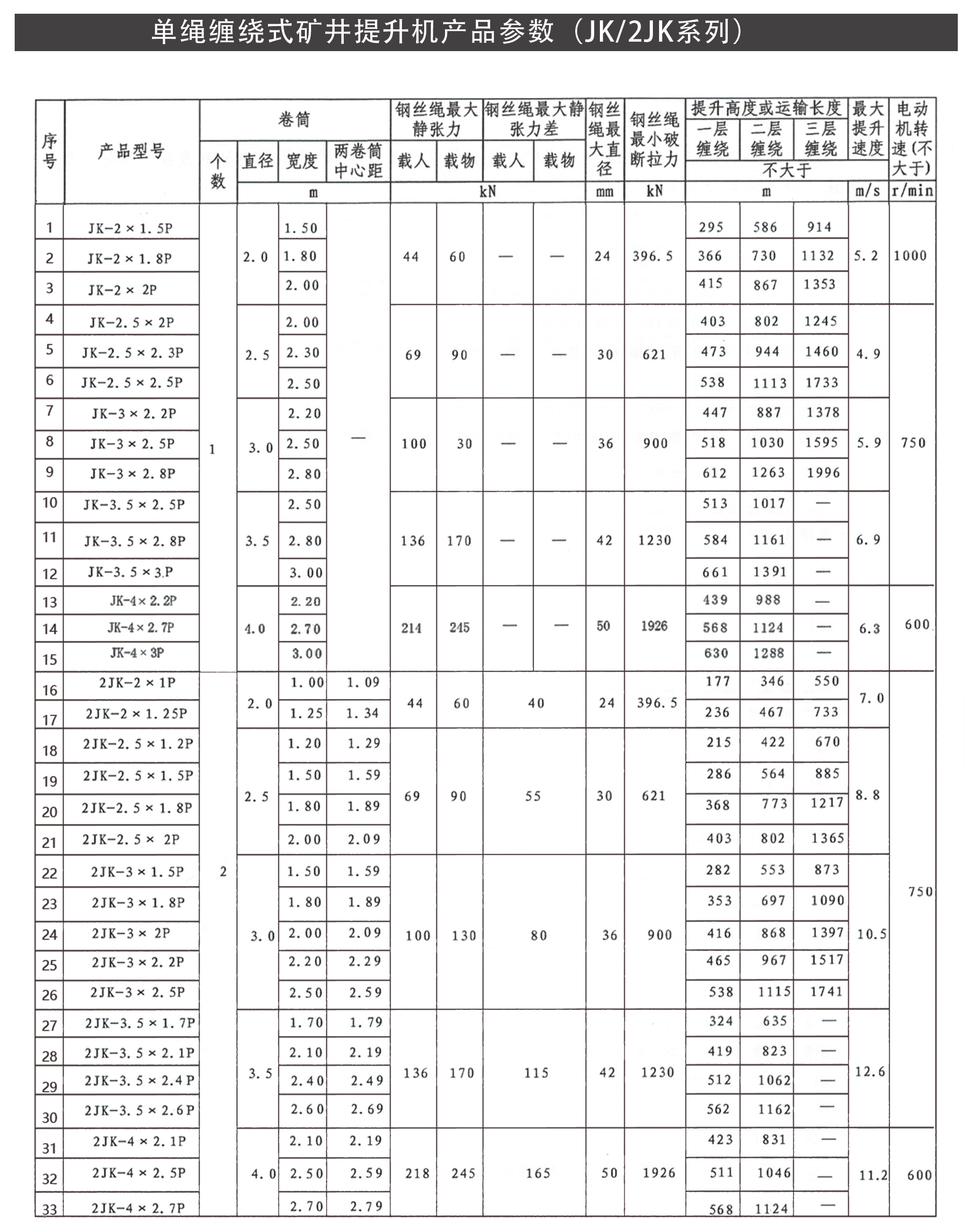

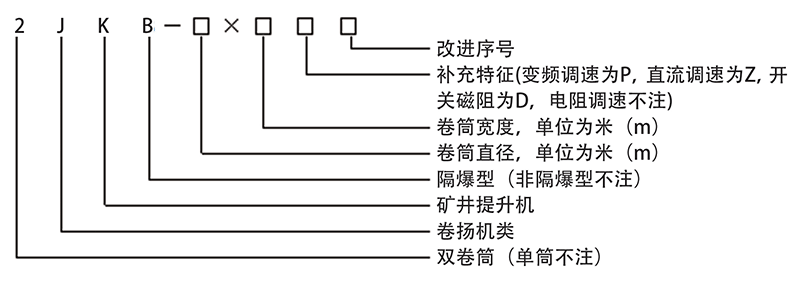

The Meaning Behind the Model Designations of Single-Rope Winding Hoists :Example: The model of the 2.5-meter double-drum hoist is: 2JK-2.5 × 1.2P 2-Double drums (1 when using a single drum, omitted for brevity) K—The initial letter of the Chinese Pinyin for "mine shaft." J- "Winch." 2.5 - The nominal diameter of the roll is 2.5 meters. 1.2 - The width between the two rope guide plates of the roll is 1.2 meters. P - AC Control; Z - DC power control. The D-electronic control system uses switch reluctance speed regulation; resistor-based speed control is not indicated. Currently available with single and dual drums Two series, 43 product specifications—ranging from large diameters of 4 meters down to smaller sizes—and customizable options available upon request. |

1. The spindle assembly can be designed as an integral type, a two-part type, or a four-lobed drum-type.

2. The drum groove features either a machined helical groove, a polygonal groove, or a helical groove formed by plastic lining and compression; additionally, steel wire rope transition devices are installed between layers.

3. The spindle and drum are connected via a flat, high-torque friction coupling;

4. Equipped with rear-mounted disc brakes powered by hydraulic cylinders, featuring protective functions such as monitoring brake pad wear and spring fatigue; optional constant-torque and constant-deceleration hydraulic stations are available.

5. A signal monitoring device composed of an optical encoder and a DC tachogenerator, featuring protective functions such as overspeed detection, overwinding protection, and depth indication monitoring.

6. Employs a hardened-plate planetary gear reducer, offering advantages such as long service life, high transmission efficiency, compact size, lightweight design, superior reliability, low noise levels, and easy, convenient maintenance.

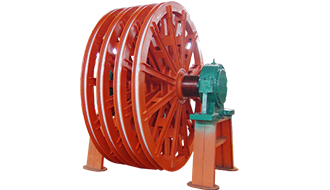

7. The hoisting sheave assembly features an integral or split welded structure, equipped with rolling bearings and friction linings mounted on the wheel flanges; it boasts high mechanical performance and excellent impact toughness.

8. Utilizes a radial tooth-block type rope-adjusting clutch mechanism; this system enables quick and precise rope adjustments, boosting operational efficiency while eliminating the previous risk of oil leakage from cylinders potentially contaminating the brake disc.

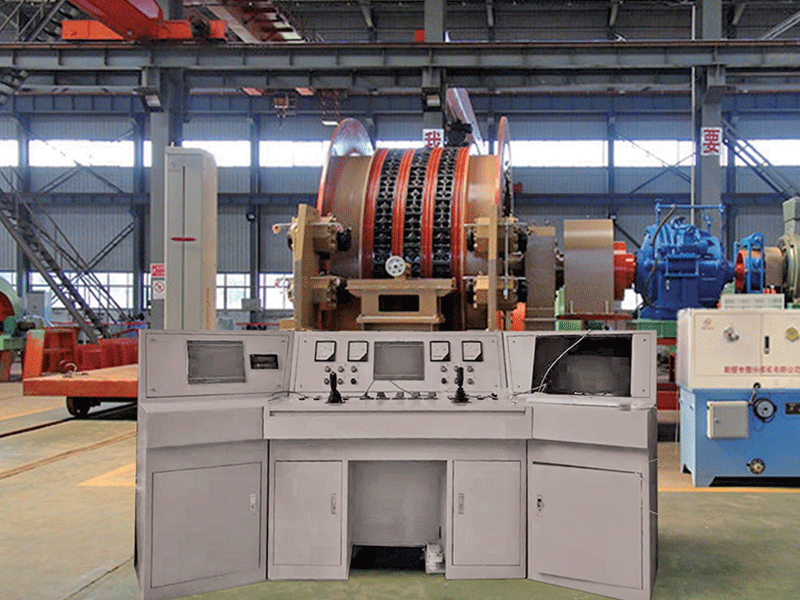

9. Complete set of variable-frequency electrical control system: The control system utilizes PLC technology, offering comprehensive fault monitoring and reliable fault alarm protection features. It includes multiple protective functions such as overvoltage, overcurrent, undervoltage, short circuit, ground fault, and overheating.

Hebi Yuxing Coal Machinery is committed to providing users with comprehensive, integrated turnkey solutions and equipment for mine hoists.

Friendly Reminder If you have any other questions about our winch hoists, feel free to click on online consultation or call our dedicated hotline—Yuxing Coal Machinery will provide you with professional and detailed answers.

Related Products

Leave a Message Online

Follow us

Hebi Yuxing Coal Machinery Co., Ltd.

Hotline:+86-13939219076

Technical Consultation:+86-13503925535

Address: Yuxing Industrial Park, Shancheng, Hebi City, Henan Province

You are a helpful assistant.

Copyright © Hebi Yuxing Coal Machinery Co., Ltd. SEO tags Business license

Copyright © Hebi Yuxing Coal Machinery Co., Ltd.Business license

This website supports IPv6 and SEO tags.