Welcome to the website of Hebi Yuxing Coal Machinery Co., Ltd.!

Hotline:

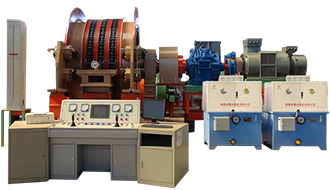

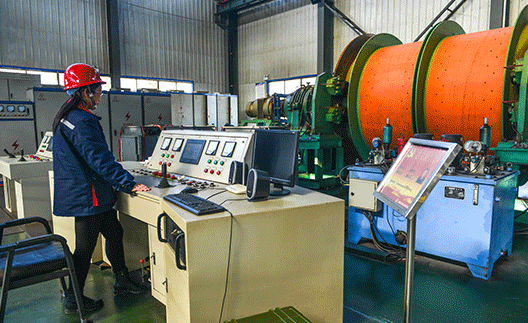

YXPD-BPHK-BPG Low-Voltage Variable Frequency Drive for Elevators

It can be used in conjunction with single-rope and multi-rope variable-frequency mine hoists for coal mines and non-coal mines. The power supply voltages available are 380V, 660V, and 1140V, including low-voltage options, making it suitable for frequency conversion speed control of AC motors ranging from 22KW to 1000KW. When paired with the YXPD-BPHK-ZKT intelligent networked master console, it enables seamless, networked intelligent control functionality.

Category:

Electrical Control Systems Series

Leave a Message Online

Product Description

Product applications and intended uses

It can be used in conjunction with single-rope and multi-rope variable-frequency mine hoists for coal mines and non-coal mines. The power supply voltages available are 380V, 660V, and 1140V, including low-voltage options, making it suitable for frequency conversion speed control of AC motors ranging from 22KW to 1000KW. When paired with the YXPD-BPHK-ZKT intelligent networked master console, it delivers a seamless, networked, and smart control solution.

Product Performance

1. This product is a hoist-specific variable frequency drive developed in collaboration with a VFD manufacturer. It employs advanced current vector control technology and supports both PG-less vector control and PG-based vector control. Featuring low starting frequency, high output torque, excellent dynamic performance, exceptional overload capacity, superior precision, smooth startup, and stable heavy-load hovering capabilities, this VFD delivers outstanding reliability and efficiency.

2. As an enhanced dedicated frequency inverter, it also features special hoist functionality: advanced applications that include all the capabilities of a standard hoist system—such as torque memory, power optimization, limiter switch monitoring, mechanical brake (holding brake) control logic, and torque verification—along with additional tailored features for precise lifting operations.

3. In conjunction with the braking unit and braking resistor, it enables four-quadrant operation of the hoist. Alternatively, when paired with the rectifier-feedback unit, it perfectly forms the control loop for AFE, featuring dual-PWM sinusoidal wave control. Both input and output currents remain sinusoidal, while the dual-IGBT main circuit ensures a high carrier frequency, significantly reducing operational noise and delivering smooth torque output.

4. Simultaneously addresses the energy recovery issue during hoist lowering, feeding the recovered energy back into the power grid—resulting in significant energy-saving benefits. It also resolves challenges posed by grid voltage fluctuations, ensuring stable operation even when input voltage variations are substantial, while maintaining consistent output torque. This ensures reliable and safe operation of both the variable frequency drive and the motor.

5. Equipped with remote monitoring and remote diagnostics interfaces, it can connect to the internet, allowing authorized users to gain remote access for troubleshooting, modifying operating parameters, and more.

Related Products

Leave a Message Online

Follow us

Hebi Yuxing Coal Machinery Co., Ltd.

Hotline:+86-13939219076

Technical Consultation:+86-13503925535

Address: Yuxing Industrial Park, Shancheng, Hebi City, Henan Province

You are a helpful assistant.

Copyright © Hebi Yuxing Coal Machinery Co., Ltd. SEO tags Business license

Copyright © Hebi Yuxing Coal Machinery Co., Ltd.Business license

This website supports IPv6 and SEO tags.