Welcome to the website of Hebi Yuxing Coal Machinery Co., Ltd.!

Hotline:

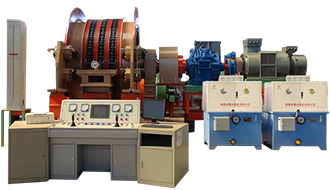

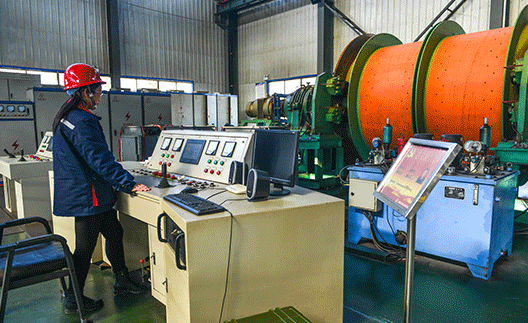

YXPD-BPHK-ZKT Intelligent Networked Console

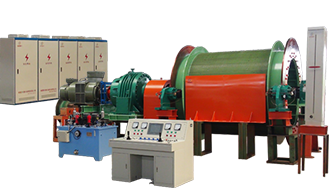

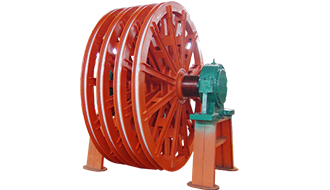

Primarily designed for mine hoists used in single-rope, multi-rope, multi-level, and vertical/inclined shafts—such as those found in coal mines, metallurgical plants, and non-ferrous metal mines—this system offers AC and DC control solutions for both new installations and retrofits in existing mines.

Category:

Electrical Control Systems Series

Leave a Message Online

Product Description

Product applications and intended uses

Primarily designed for mine hoists used in single-rope, multi-rope, multi-level, and vertical/inclined shafts—such as those found in coal mines, metallurgical plants, and non-ferrous metal mines—this system offers AC and DC control solutions for both new installations and retrofits in existing mines.

Product Performance

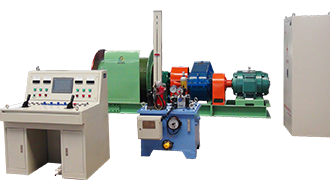

1. The YXPD-BPHK-ZKT Intelligent Networked Console serves as the control core device for the entire mine hoisting and transportation system. This equipment features a technologically advanced, highly reliable industrial PLC as its central component—though the PLC can be customized according to customer requirements.

2. The PLC-based control system features dual-PLC networked control, with each PLC serving as both a backup and a monitoring unit, along with a diversified design approach. This setup effectively mitigates potential risks associated with PLCs in specific environments. Adhering to the safety circuit’s dual-wire design principle, the system achieves comprehensive protection for the hoist through its dual-wire configuration.

3. Integrated with a host computer monitoring system for a more intuitive display of the hoist's trial operation status. Successfully implemented logic, time, speed, and position control throughout the hoist's operational process, including speed profiling based on stroke requirements, as well as safety protection mechanisms for various scenarios and automated start-up controls—along with comprehensive displays of all operational states.

4. Equipped with a comprehensive remote diagnostics and remote monitoring system, featuring a network interface that allows seamless integration into other network monitoring systems.

5. Achieve digitalization of the speed control system, networking of the control system, and intelligent monitoring system;

6. Offers flexible operation modes, including unattended operation, remote start-up, and seamless speed adjustment in fully automatic, semi-automatic, or manual settings.

7. Constant speed, deceleration, crawling, and precise stopping—ensuring stable lifting and accurate parking (particularly suited for multi-level lifts, enabling individual level call-based start/stop operations). The manual operator can freely adjust the running speed, allowing customization based on actual conditions.

8. Maintenance Inspection: Manually reduce the hoist speed to crawling speed for thorough inspection of all hoist components.

Related Products

Leave a Message Online

Follow us

Hebi Yuxing Coal Machinery Co., Ltd.

Hotline:+86-13939219076

Technical Consultation:+86-13503925535

Address: Yuxing Industrial Park, Shancheng, Hebi City, Henan Province

You are a helpful assistant.

Copyright © Hebi Yuxing Coal Machinery Co., Ltd. SEO tags Business license

Copyright © Hebi Yuxing Coal Machinery Co., Ltd.Business license

This website supports IPv6 and SEO tags.